Pioneering the Path: The Prominence and Prospects of Cobots in Modern Industries

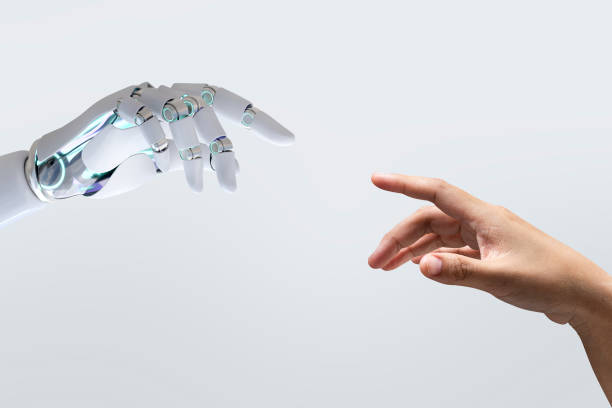

While robotics has been a staple in industrial operations for decades, the emergence of collaborative robots—or cobots—has marked a significant shift. These robots are designed to work alongside humans in shared workspace, offering a unique fusion of automation and manual labor. Born of the necessity to enhance safety and productivity, cobots have evolved from a novel concept in the late 1990s to a key element of modern industrial operations.

Cobots and Current Business Trends

Today’s industries are witnessing a surge in cobot adoption. Thanks to their versatility, adaptability, and user-friendly interface, cobots are being utilized in a variety of sectors—from manufacturing and automotive to healthcare and hospitality. They are transforming business operations, helping to optimize production, reduce costs, and increase output quality.

The Impact of Cobots in Industrial Processes

The introduction of cobots into the workplace has prompted significant changes. On one hand, they offer numerous benefits such as improving operational efficiency, reducing workplace injuries, and enabling greater flexibility in production lines. However, they also present challenges, including the need for workforce training and potential job displacement.

Cobot Adoption: Backed by Research

Recent research underscores the growing prominence of cobots. According to a report by Interact Analysis, the global cobot market is forecasted to reach $9.3 billion by 2025, reflecting a compound annual growth rate of over 30%. This rapid growth is attributed to the unique advantages cobots offer, such as their ability to perform complex tasks with precision and consistency, even in small- and medium-sized enterprises.

Balancing Technicality and Accessibility

While cobots represent a significant technological advancement, their adoption does not necessitate specialized expertise. Most cobots are designed to be user-friendly and programmable through simple interfaces, making them accessible to a wide range of workers. This balance between technical sophistication and ease of use is a key factor in their growing popularity.

Practical Insights into Cobots

- Cobots can be deployed in a variety of tasks, including assembly, inspection, and packaging.

- Unlike traditional industrial robots, cobots require minimal safeguarding, as they are designed to operate safely alongside human workers.

- Cobots can be reprogrammed and redeployed easily, offering flexibility to meet changing production needs.

- Investing in cobots can lead to significant cost savings in the long run, as they can operate continuously with minimal maintenance.

Wrapping Up the Cobot Conversation

As we navigate the evolving landscape of industrial operations, the rise of cobots represents a pivotal shift. These collaborative robots are reshaping the way businesses operate, offering a unique blend of efficiency, safety, and flexibility. While they pose certain challenges, the benefits they offer make them a valuable asset in today’s dynamic industrial environment. As cobots continue to gain traction, they are set to play an increasingly central role in the future of industrial operations.